The different types of centrifugal pumps include:

12V Pumps

These pumps operate 12 V DC, with a maximum flow of 330 GPH. It consists of alligator clips, a battery cable, and an on/off switch for ease when operating. The lowest height of water being pumped out can be 1/8 inches with the suction strainer, and the largest height of water being lifted is 40 feet. 3/4 inches garden hose adapter at both outlet and inlets, 6 feet suction hose, gasket for replacement, and an extra impeller. It can be portable due to its lightweight. In that case, a carrying handle can be attached to the body for convenient use.

Chemical pumps in Kenya

Chemical pumps are designed specifically for use in pumping chemicals that are resistant to corrosive materials, which makes it suitable for handling corrosive and abrasive industrial liquids such as paint, fuel, solvent, bleach, and many others. A pump that contradicts the chemical can result in brittleness or dissolving, swelling, and ultimately it will leak and fail. Special consideration needs to be given to the materials of a chemical transfer pump, along with the concentration and temperature of the fluid being handled. Whenever there is required a chemical dosing pump, one for tank to tank transfer or a barrel emptying pump, the pump can be tested.

Radial Pumps in Kenya

In radial centrifugal pumps, the fluid comes out of the impeller after rotating for 90 degrees relative to the suction. Many centrifugal pumps are found in this category. Fluid enters through the horizontal suction flange and leaves through a vertical outflow flange. The discharge will be perpendicular to the pump’s shaft. This design is commonly used when there is a flow limitation and a need to raise the discharge pressure. Thus, radial design is a low flow rate and a high-pressure pump. Most pumps that are used in the gas and oil industries fall into this category.

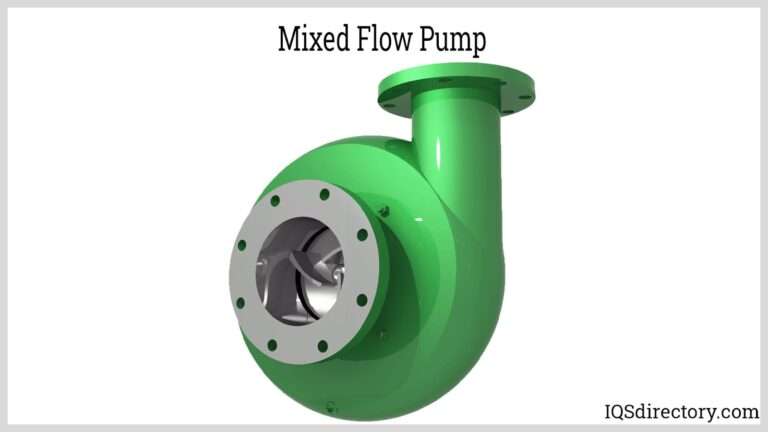

Mixed Pumps in Kenya

As the name states, in a mixed flow centrifugal pump, the fluid flow mixes both axial and radial properties. That is a trade-off between radial and axial pumps. Mixed pumps operate at a much larger flow rate with a decent increase in the head.

TRASH PUMPS IN KENYA

These pumps are portable pumps and are generally for dewatering applications. They are planned to pump large amounts of water that contains soft and hard solids such as mud, twigs, leaves, sand, and sludge. Most trash pumps are heavy-duty, portable centrifugal pumps that have larger discharge openings and deeper impeller vanes than other pumps. Trash pumps are capable of processing materials with some suspended particulates that can clog other centrifugal pumps and can move hundreds better yet thousands of gallons per minute. The materials that enter the pump are not grounded in the trash pump. They are designed to have a large discharge opening, pump housing, and deep impellers veins. The pumps can be made from cast iron, steel, aluminum, and stainless steel. Most of these pumps have roll cages.